Products All

Vitrified bond Diamond & CBN Wheels

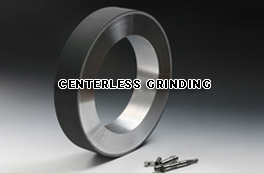

Global Tools Co.,Ltd, provides the top quality vitrified bond diamond and CBN wheels such as cam shaft grinding wheels, bearing internal grinding wheels, compressor bearing internal grinding wheels, ball screw grooving grinding wheels, injection nozzle grinding wheels, constant velocity ball joint grinding wheels, and PCD & PCBN insert grinding wheels.

VITRIFIED BOND

Vitrified bonded diamond and CBN wheels are extremely hard, providing very high stock removal rate and wear resistance. Vitrified bonded wheels are working very efficiently giving excellent surface quality. They are perfect choice when material is sensitive to heat and high machining accuracy is required. Profile stability and grinding times are also advantages of vitrified bonded wheels. Typically used for bruising, PCD/PCBN insert sharpening, internal grinding (ID grinding), camshaft, crankshaft, cylindrical grinding and other operations.

Vitrified bond technology to the super abrasive, CBN and Diamond is developed for the increasing demand in the recent main industry.

Vitrified bonded CBN wheel is available to grind the "difficult-to-grind" metal such as high speed steel.

Vitrified bonded CBN wheel is also available to grind the "semi-difficult-to grind metal, which is main work piece in the leading industry such as SCM, with high grinding performance.

Vitrified bonded Diamond wheel shows an excellent grinding performance to the various ceramic materials.

Vitrified bond of super abrasive wheel is characteristic of (1) high material removal rate (2)excellent dress ability (3)least wheel wear (4)longest dressing interval.

It provides a long tool life, effective grinding, high productivity and excellent grind-ability which is desperately sought after to provide maximum performance with minimum maintenance.

Products

Vitrified Bond

Vitrified bonded diamond and CBN wheels are extremely hard, providing very high stock removal rate and wear resistance. Vitrified bonded wheels are working very efficiently giving excellent surface quality. They are perfect choice when material is sensitive to heat and high machining accuracy is required. Profile stability and grinding times are also advantages of vitrified bonded wheels. Typically used for bruising, PCD/PCBN insert sharpening, internal grinding (ID grinding), camshaft, crankshaft, cylindrical grinding and other operations