Product 2 : RESINOID BOND

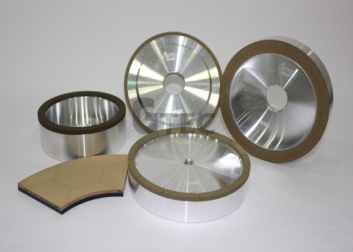

Resin bond Diamond & CBN Wheels

For non-ferrous metal cutting, carbide & ceramic grindings and hardening steel machining.

Global Tools Co.,Ltd, provides the top quality diamond and CBN tools such as diamond centerless grinding wheels, creep feed grinding wheels, diamond wheels for grinding carbide and steel combination, diamond wheels for cemented carbides insert, double disc grinding wheels, diamond flaring cup wheels, and tip saw grinding wheels.

Resinoid Bonds

Resinoid Bonds are made from phenolic type plastics or resins and cured in ovens under carefully controlled conditions of temperature ranging between 150 c to 200 c. Resin bond grinding wheels are ideally suited for high operating speeds and also for heavy duty of operations. Resin bond grinding wheels give very good removal rates, are particularly free cutting and cause only very little workpiece damage even at high removal rates. They are normally used for grinding tungsten carbide, cermet, high alloy steels and other hard metals. Resin bonded wheels, which can be phenol bond or polyimide bond, feature high wear resistance, self-sharpening ability, heat conductivity, grain holding properties and great surface finish. Proper choice for sharpening and profiling, surface, centerless, cylindrical and other types of grinding applications.

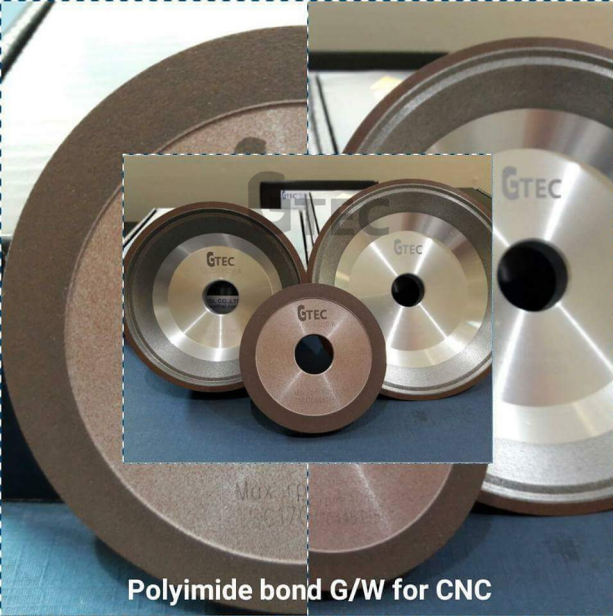

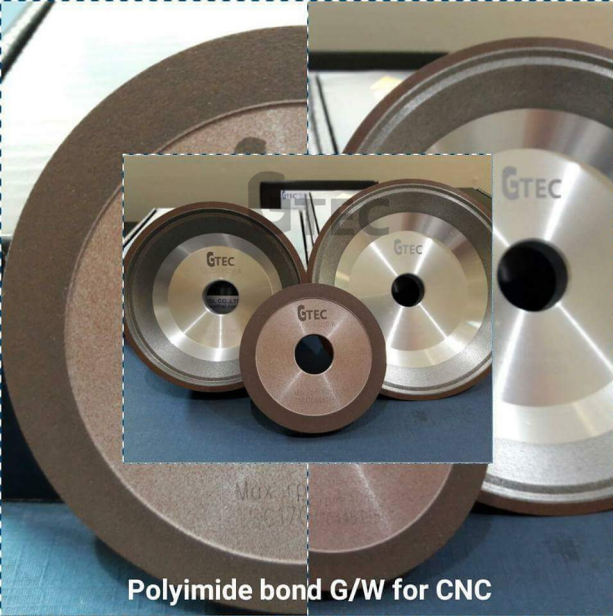

For resin, we can offer two types of bonds :

- Phenol bond- mostly used for general purpose, mostly dry grinding.

- Polyimide bond – mostly used type of bond, for its great wear resistance, high stock removal rates, shape holding and durability.

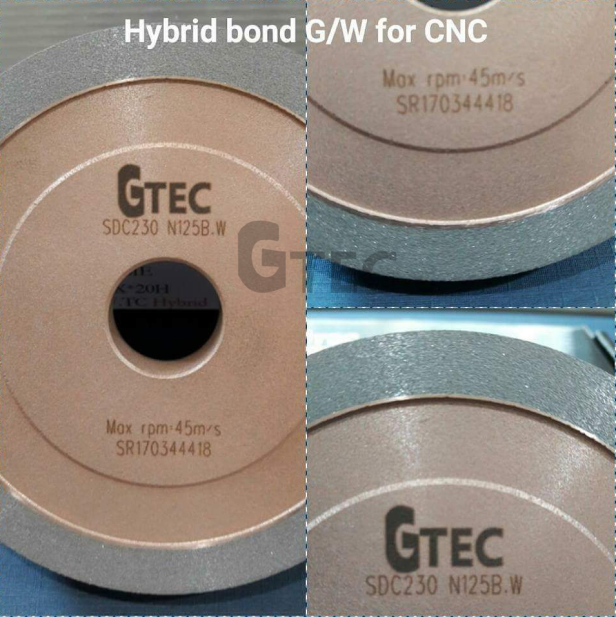

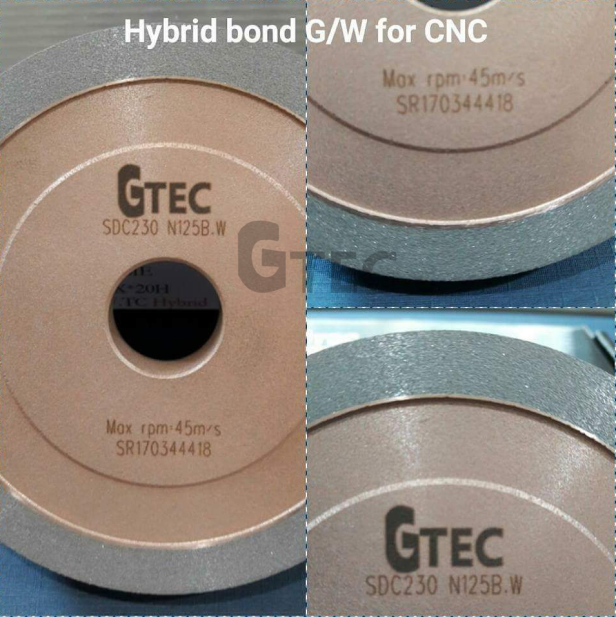

Hybrid Bond

Hybrid bond is usually used on high-tech CNC tool and cutter grinders for new tool manufacturing or resharpening. Wheels produced using hybrid bond boasts very long lifetime, reasonable heat dispersion, very high stock removal rate and fast feed speed. Hybrid bonded wheels provide clean surface finish without heavily loading the spindle. With very long truing intervals hybrid bonded wheels are best choice for fluting, gashing, clearance and burr processing operations. Hybrid bonded wheels is the best choice for efficient and productive grinding operations.

Main industry use Resin bond diamond & CBN Wheels :

- Tooling industry : Tungsten carbide tool

- Automobile industry

Workpiece :

- Tungsten carbide tooling, bearing, transmission gear washers, tappet shims, compressor parts, vane pump vanes and rotors, precision springs, etc

- High-speed tool steel, die steel, bearing steel, carbon tool steel, spring steel, cast iron, sintered ferrous metal, etc

- High-speed tool steel, cemented carbide alloy, cermets, ceramic, diamond compact, CBN compact and other super-hard materials.